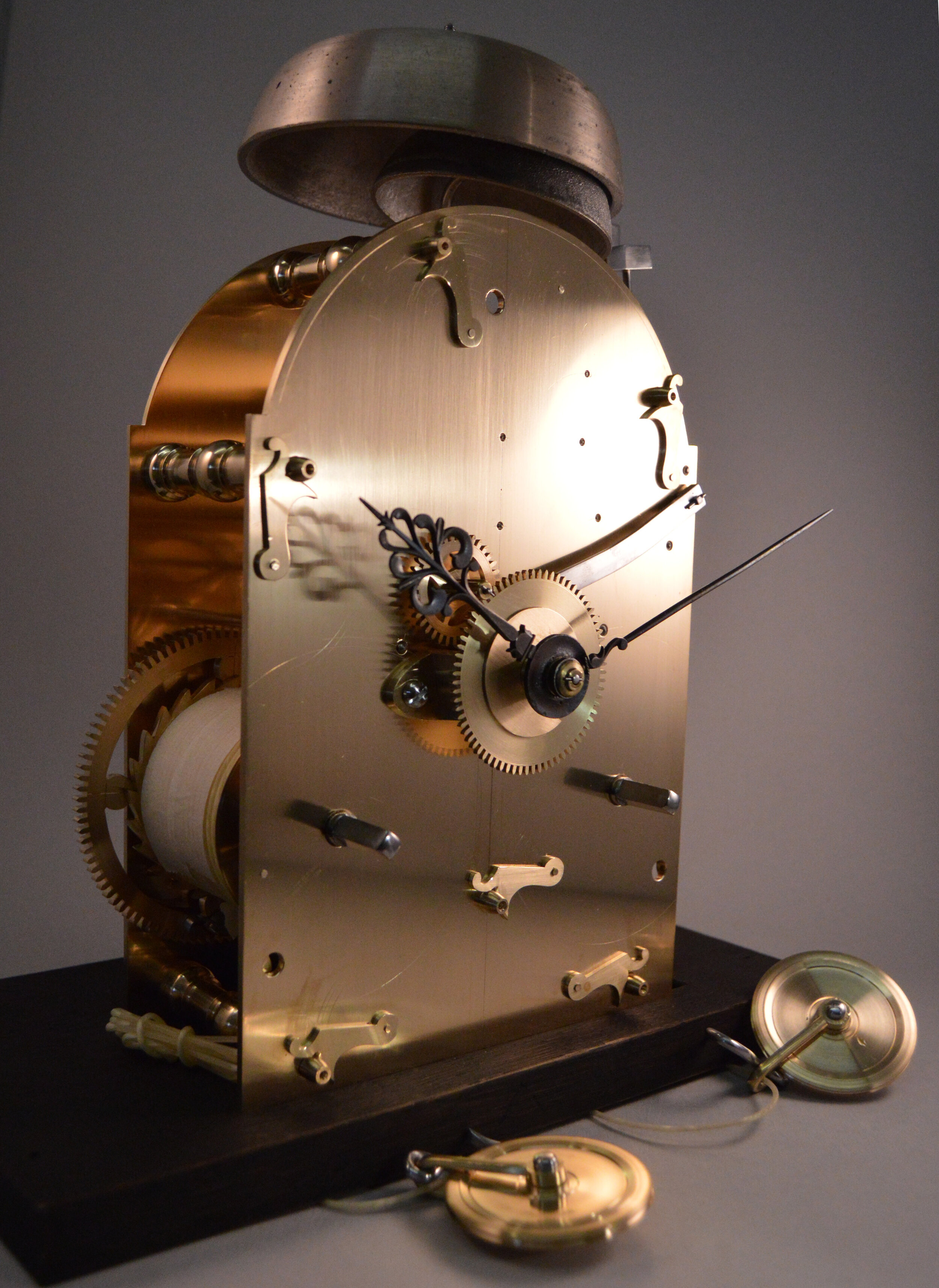

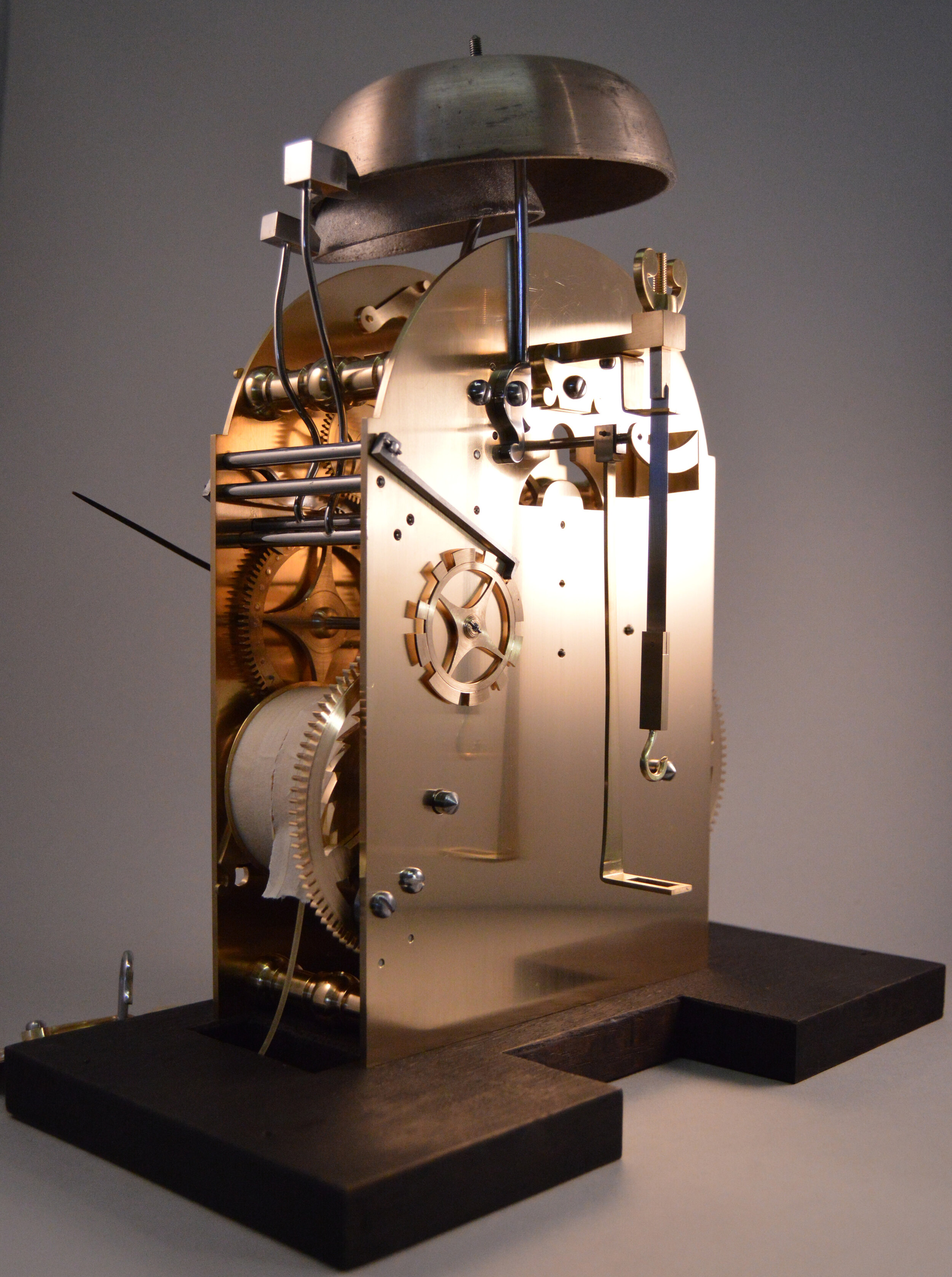

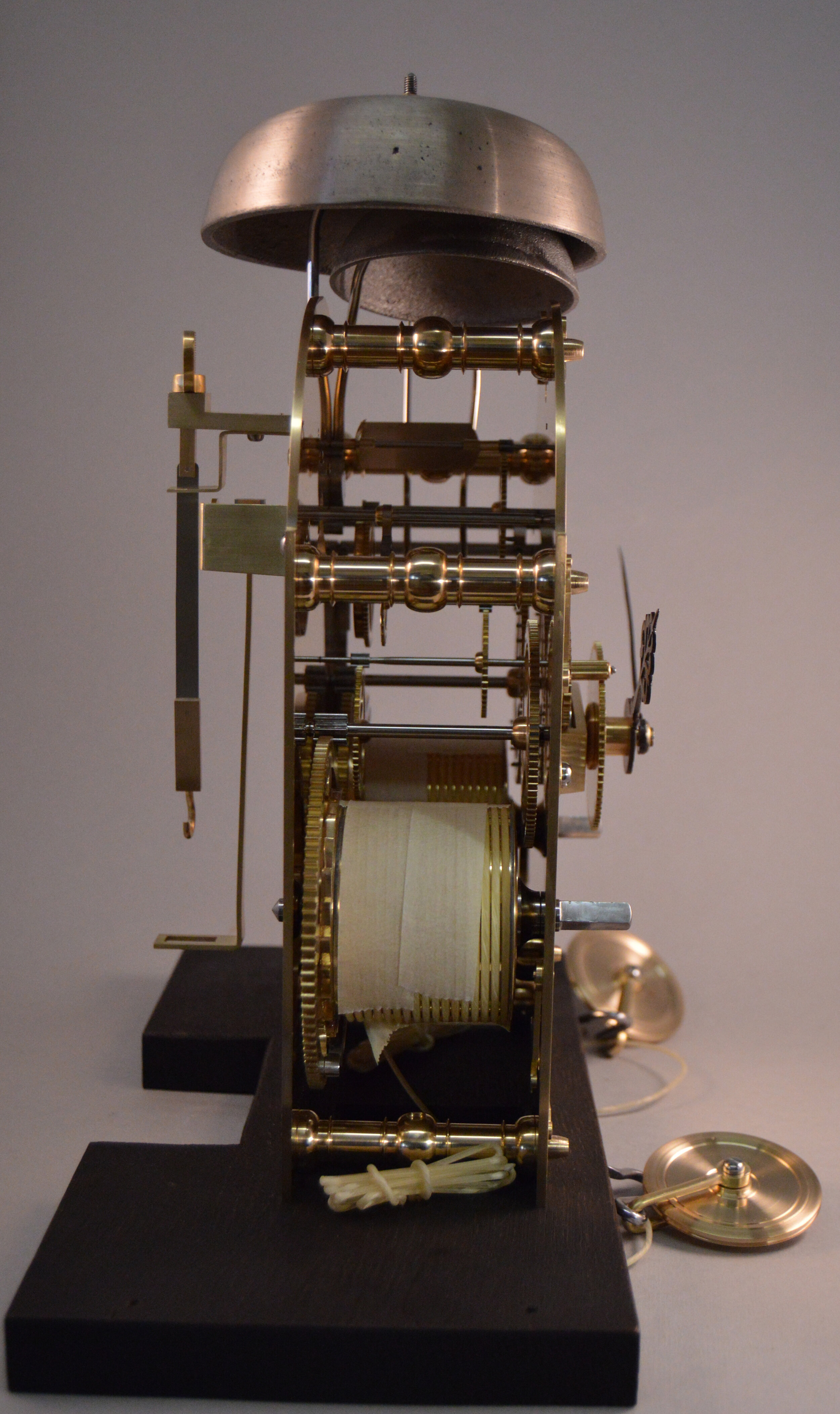

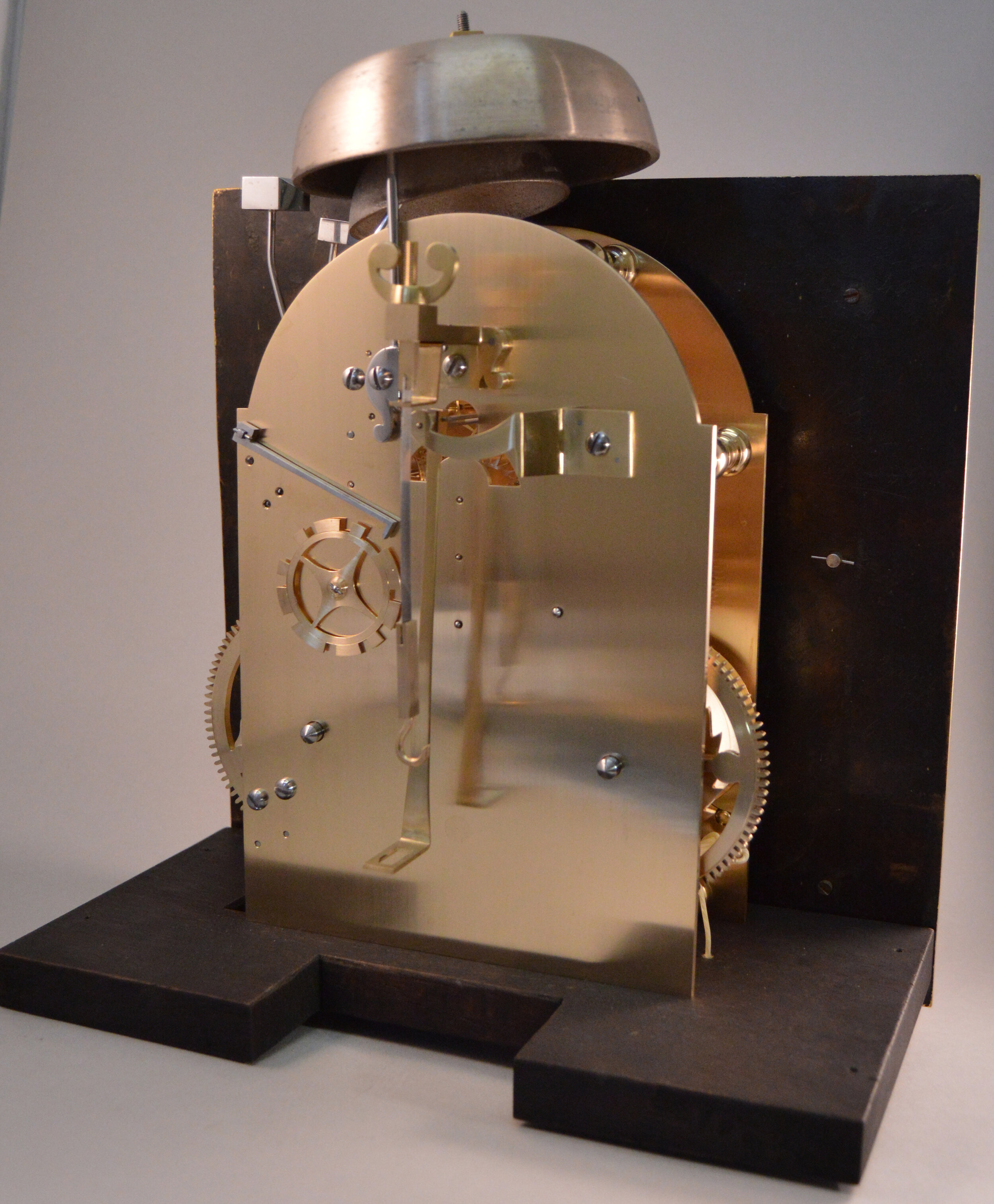

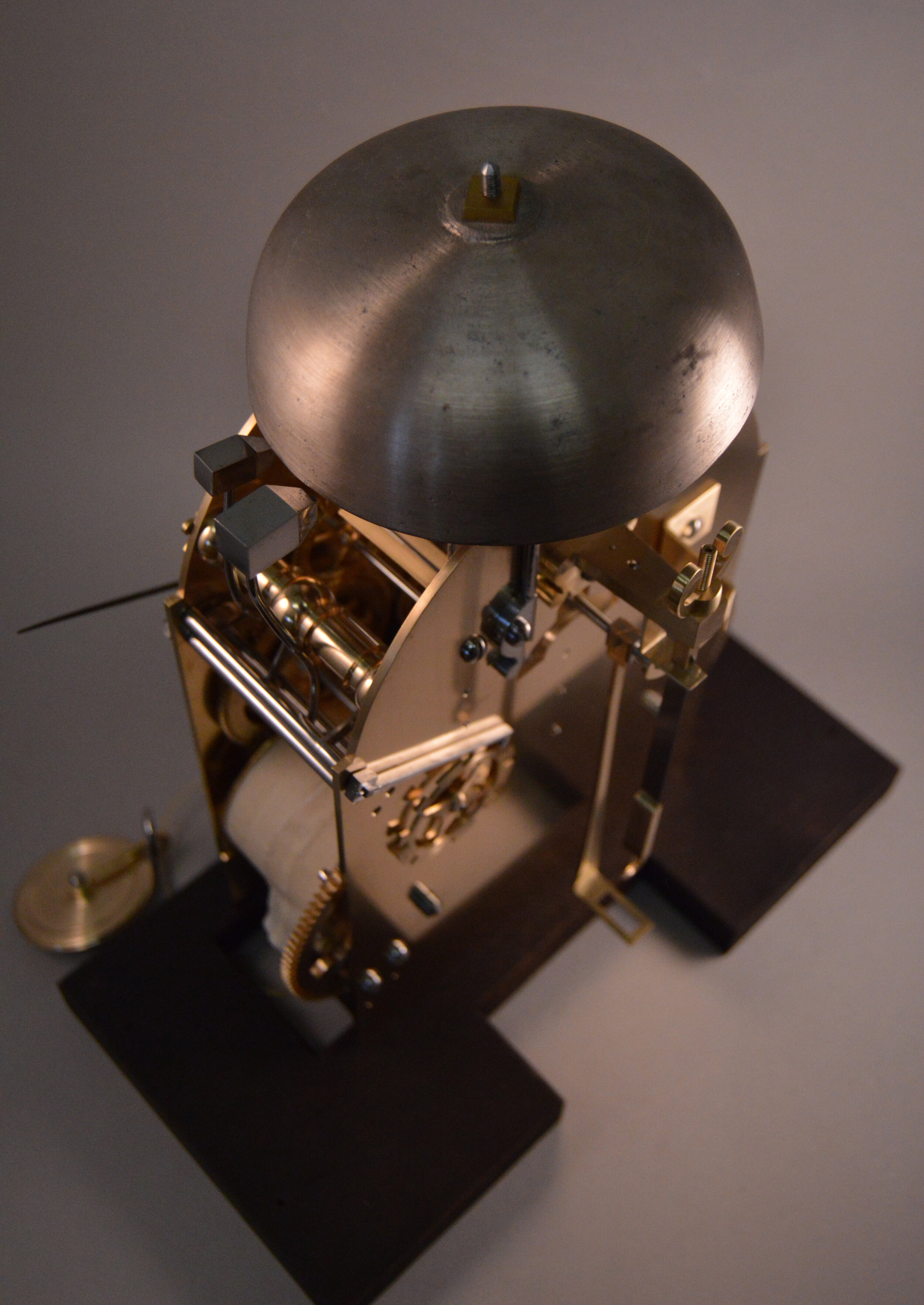

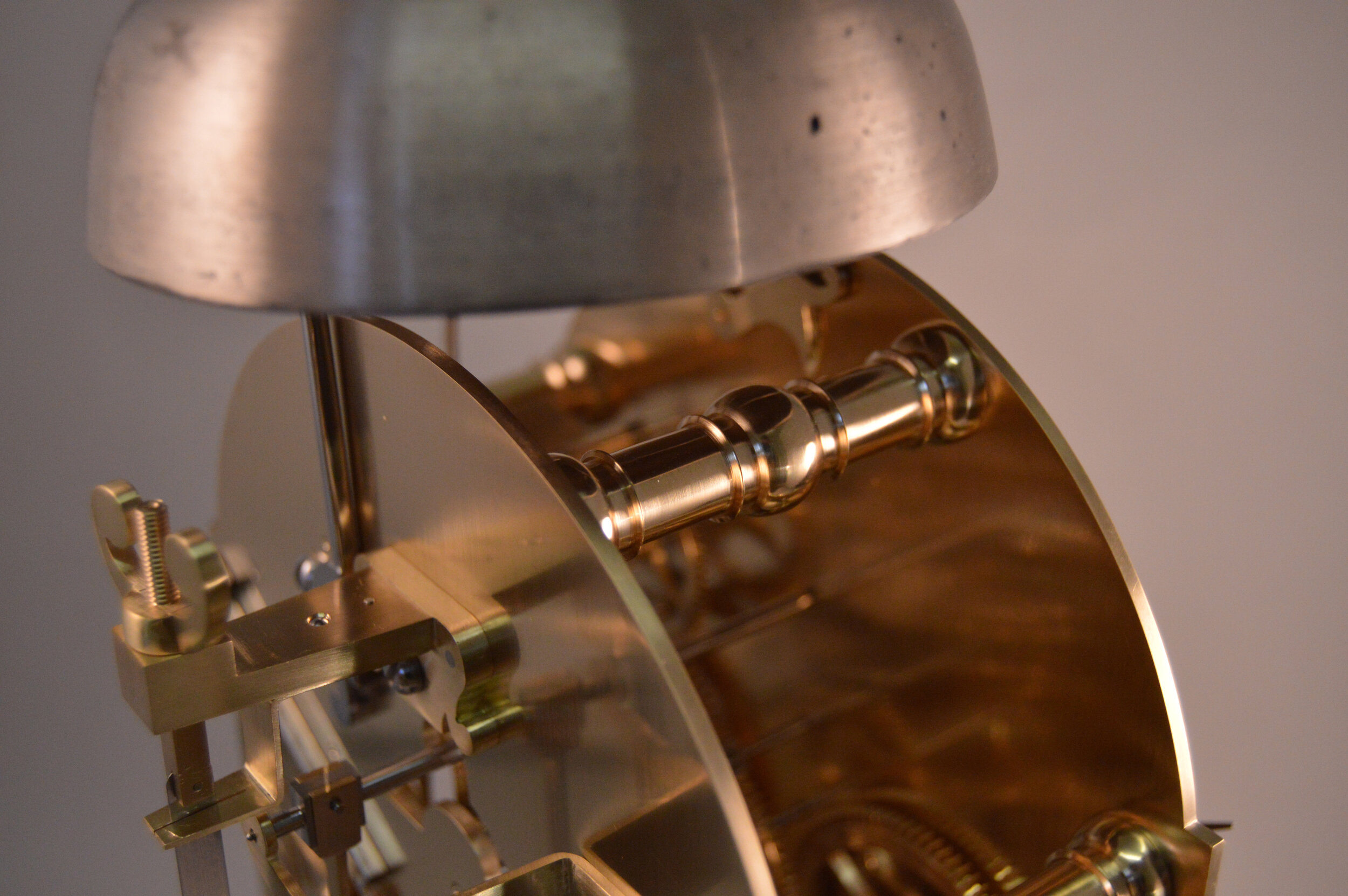

Reconstruction/Replica - Joseph Knibb Longcase Clock, 3 Month Duration, Roman Striking, 1 1/4 Second Pendulum. Circa 1675 - Made by Tommy Jobson 2017

This project originally came about as part of some routine maintenance/restoration work for a private collection. When I was assessing the clocks for work I noticed that one of the longcases had a rather special looking dial. The thing that attracted my attention was the ‘IV’ numeral for ‘4’ as this is a rare feature. Traditionally on a clock dial, the number 4 is displayed as four strokes, ‘IIII’. This is not technically correct for the Roman numbering system, however, is traditional for the conventional clock dial. One maker however was known for using ‘IV’ as it hinted at a special function in some of his clocks – Joseph Knibb.

Roman Striking

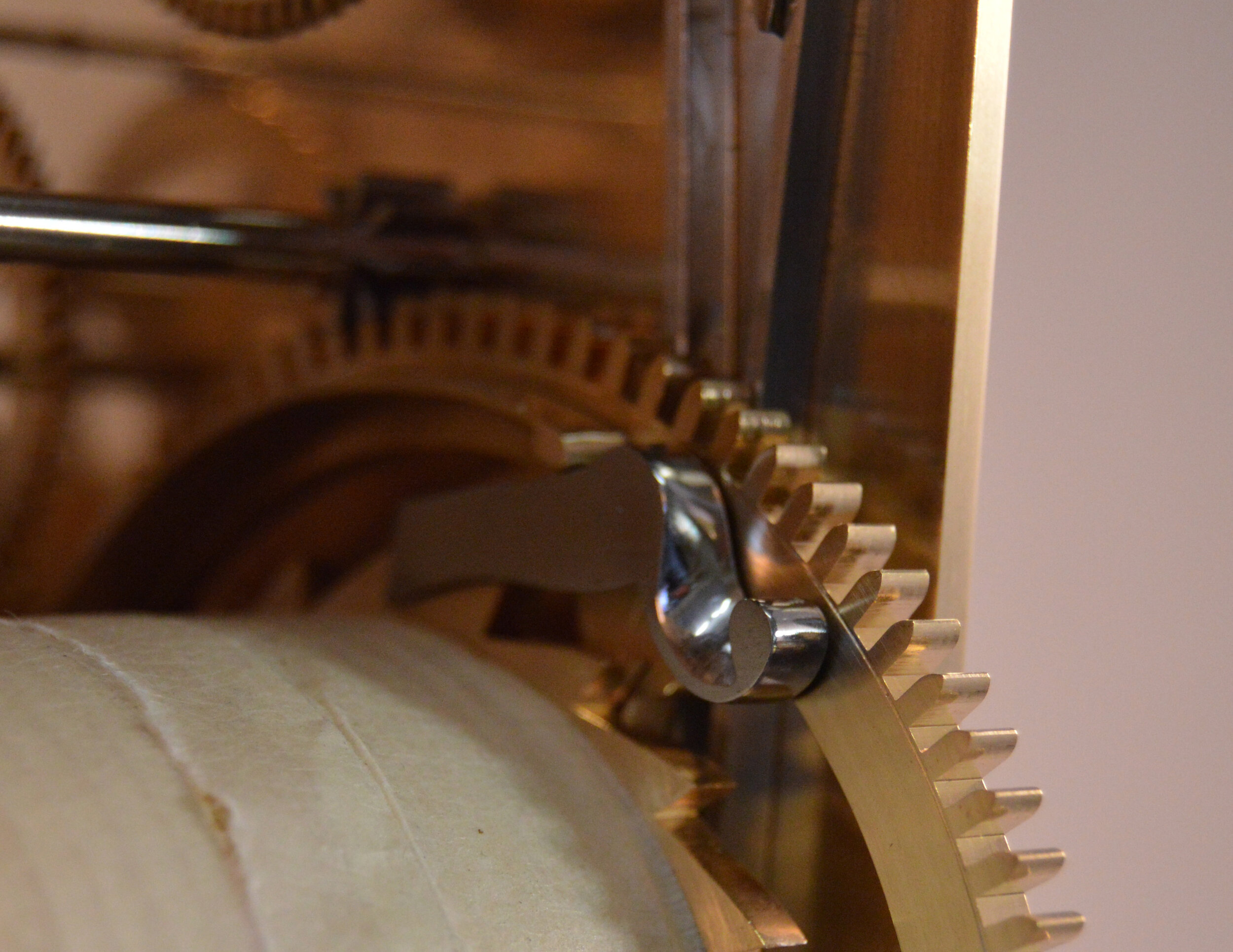

A clock traditionally strikes 1 – 12 on a single bell to denote the hours. This is fine, however, it does mean that a relatively large number of blows of the hammer are needed, and hence a lot of power. Over a week 1092 blows or strikes of the hammer are needed. The Roman striking system was a clever alternative as it greatly reduced the number of blows required in the same period. Instead of striking 1 – 12 on a single bell, the system uses two bells of different pitches, one bell denoting the ‘I’s and the other the ‘V’s. This means the clock can sound the Roman numerals as they are displayed. For example, 4 o’clock is ‘IV’ in Roman numerals, so one blow on the ‘I’ bell and one blow on the ‘V’ bell. The improvement is particularly noticeable at 12 o’clock where instead of 12 blows only 4 are needed, 2 on the ‘V’ bell ( 2 ‘V’s making an ‘X’), and 2 on the ‘I’ bell. The improvement in power consumption is massive as the clock now only requires 420 blows over a week. Joseph Knibb On closer inspection of the dial, I was disappointed to find that all trace of the original Knibb movement had long gone, nothing of the original clock remained except for the dial and hands. The dial was now housed in a Victorian Mahogany long case and had a matching Victorian 8 – day movement behind it. When the time came to assess the clock for work I explained to the client exactly what the clock would originally have looked like and provided some research and photographs to help him visualise the object. I explained that it would be lovely to reconstruct the clock as a replica making use of the original dial and hands. This would mean reverse-engineering the movement and making a case. The client liked the idea and so the project began.

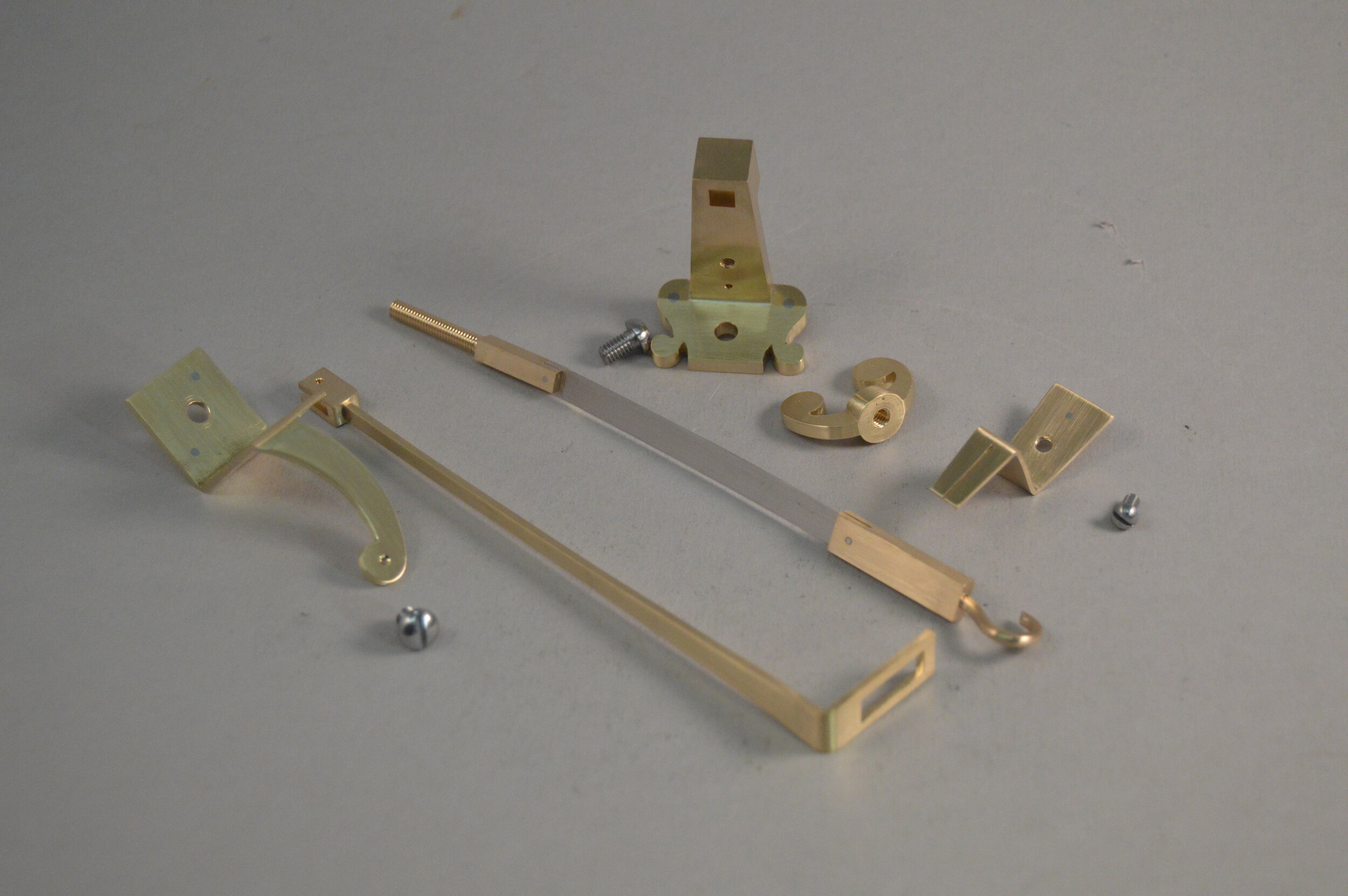

Movement

The dial still had it’s original winding holes (as well as some later ones which had to be plugged). These winding holes were located very close to the chapter ring and low down. The dial was also of a particular style and extremely fine quality. These clues all pointed to a particular style of movement made by Knibb which I refer to as his ‘humpback’ movements. These movements all had Roman striking as well as a 1 ¼ second pendulum and ran for 3 months duration. I had seen examples of these movements in the past, but never handled one personally. Unfortunately, due to their extreme rarity is was extremely difficult to arrange to view any original examples in person, so armed only with images and notes gained from other restorers I set to work reverse-engineering the movement from scratch. There is a link to a gallery of images of this work at the bottom of this page.

The images to the left are of an original example sold at Christies in June 2008 - “LOT179 A fine Charles II ebony and gilt-brass mounted Roman striking longcase clock of three month duration JOSEPH KNIBB, LONDON. CIRCA 1675 Price realised GBP 145,250”

The dial was in extremely original condition and only required light and sympathetic restoration work. I plugged the Victorian winding hole by replicating the matting on a separate sheet of brass and then cutting out two discs which could then be glued into the holes. This meant an acceptable level of camouflage but did not require me to touch the original dial in an invasive way at all. New dial feet had to be made as the Victorian ones had been fitted in different locations and were not useable. The original dial feet locations were used.

Case

The case was hand made by Piotr Dulleck and hand-finished by Guy Marshall. The carcass is of Oak and it is veneered in Pear before being ‘Ebonised’ with an oiled black finish. This is traditionally how these clocks were made and these styles of construction were adhered to. The case has a ‘rising hood’ as is contemporary for the period. The finials and feet are the typical Knibb ‘squashed ball’ type and were turned as Pear patterns by Piotr before being cast in ‘yellow’ brass and finally gilded.

This was an extremely rewarding project to complete and although a replica of an original clock I consider this to be my clock No. 1.